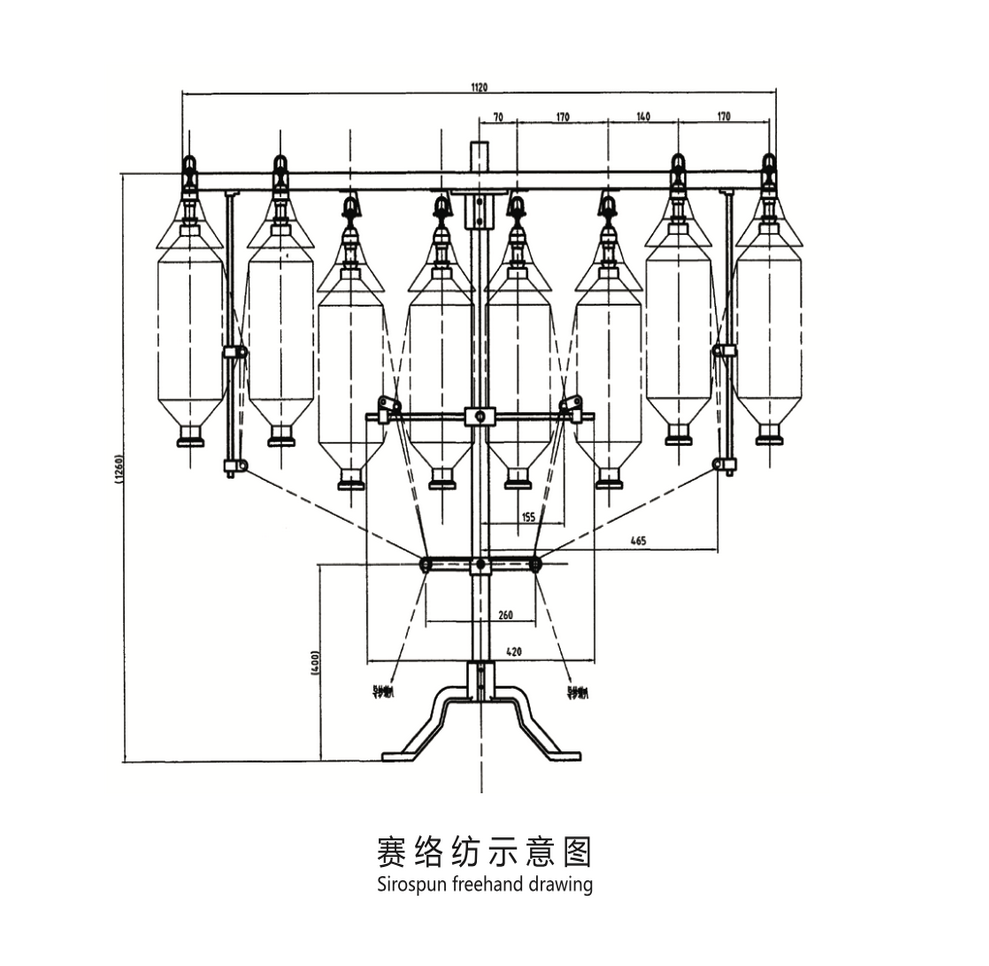

Sirospun Device(Spindle Roving Bobbin Hanger Creel)

一:Spinning theory

After two parally roving go into draft zone to output by the front rollers, that is form to one triangle area, to collect one point, then combine twisting and winding to bobbin, rotation of spindle and traveler is form to twisted yarn the twisting from bottom to top transfer to the fripping place of front roller.

二: The structure of creel

Long sirospun device: 8 raw roving of creels (roving volume expend double), A yarn and B yarn each four rows. The distance of roving is 140mm. It demands to form roving ≤ 135mm(spindle gauge:70mm). Both A and B yarn feed on double top guide trumpet (top and bottom welt, left and right welt) that go into draft zone. The detail of installation size and the rang of roving, follow picture.

Sirospun Advantage:

Yarn quality has less hairness, the strong strength, good evenness, simple operation, less investment, at meantime the device can work with compact device, slubby yarn device, and spandex core-spun device. It suit for spin different kinds of yarn.