一:CFJ Compact Spinning Assembly Introduction

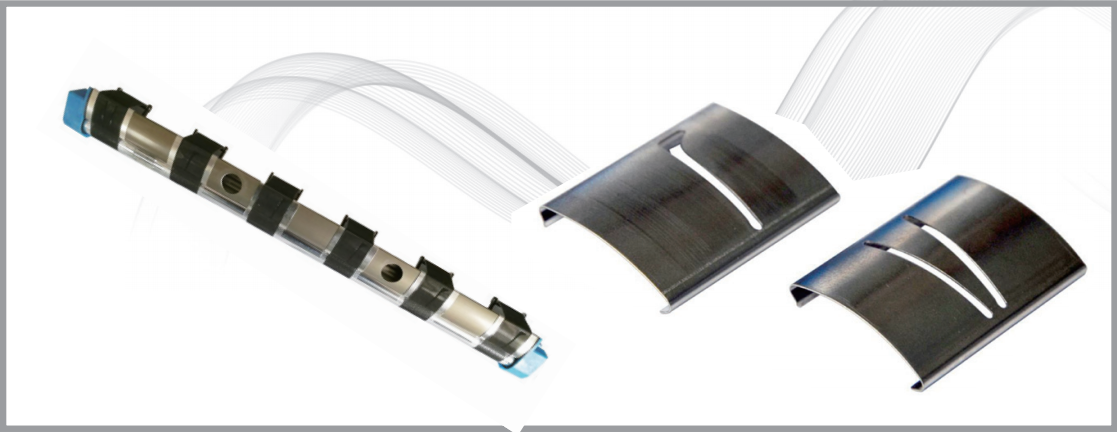

Compact spinning system developed by our company is adopted mesh apron structure of active transmission, it mainly consist of following parts such as special pipe(also known as negative pressure pipe),mesh apron & tensioning device output roller, belt tooth front roller, idle gear accessories, output roller (roller) rubber cot brakes, roller stand and negative pressure system components of compact spinning. For the machine, toothed output roller is installed in the special tube, Toothed front roller Output driving force to toothed output roller through idle gear mesh apron conduct active transmission under action of toothed output roller compact spinning ran is installed in the rear of machine, it provides negative pressure pipe through the total wind pipe. As for character of structure characteristics of domestic spinning machine, the device adopts six spindles as a unit of modular designing; it is suitable for renovation of old machine and new machine. The spinning technology can conduct fiber contraction and agglomeration through the negative pressure airflow, this, fiber conduct quick and effective agglomeration and straightness towards spun center on the edges of spun, we could minimizing the spinning triangular space, we could greatly reduce outer yarn hairiness, we improve utilization of fiber strength and yarn strength during the process.

With 4-roller structure, the roller clamps grid ring to actively drive. It is applicable to domestic and matching and transformation.

Air suction system is connected by transparent glass tube and will not affect the sight of spinner!

Special-Shaped tube is of optimum design, equipped with wear-resistant sheet to increase service life and convenient to change compact spinning and siro compact spinning; with optimum design of compact spinning wear resistant sheet, it prolongs grinding cycle of roller, increases service life of roller and save using cost for customers. It is convenient to change grid ring and tension rack.

二:Spinning environmental requirements

Temperature, humidity and air dust concentration requirements in spinning workshop:

1.1 Temperature: 25~30° all the year

1.2 Relative humidity: 55% ±5℃(cotton)

1.3 Air dust concentration < 3mg/m^3

Recommended to configure travelling cleaner

三:Use effect of CFJ compact spinning device

1. Reduce fuzziness, and the fuzziness over 3mm can be reduced by 60% above;

2. In the same spinning conditions, the finished yarn strength is improved 5%-15% more than ordinary ring spun yarn;

3. Improve CV value in spinning production;

4. Improve work enviroment and reduce flying in workshop.

四:Transformation and Installation

Use this equipment to transform the spinning machine for compact spinning, which will not damage any component of the original equipment and only needs to change drawing part, roller seat, front roller, suction flute and rear bellows. It can work only by adding compact spinning parts in addition.